Control & Automation Services

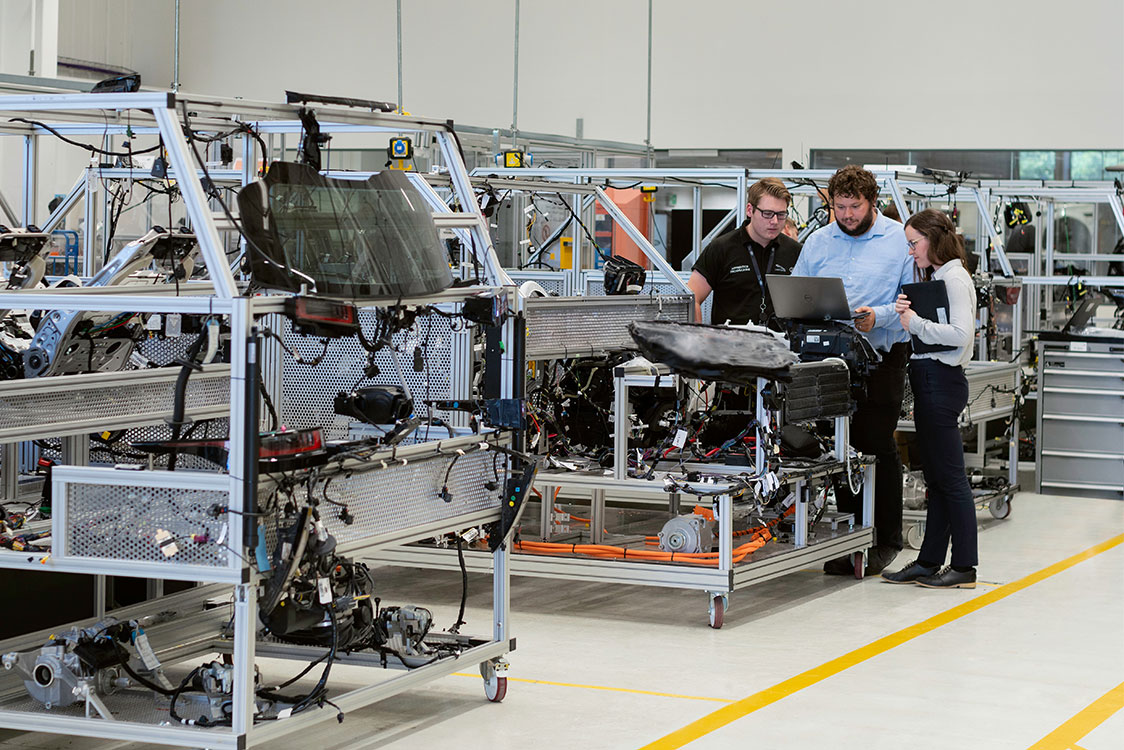

At KSOFT ENGINEERING CONSULTANCY SERVICES, we specialize in cutting-edge PLC programming and seamless system integration solutions designed to optimize your industrial processes. Our expertise ensures that your systems work together flawlessly, enhancing efficiency and reliability.

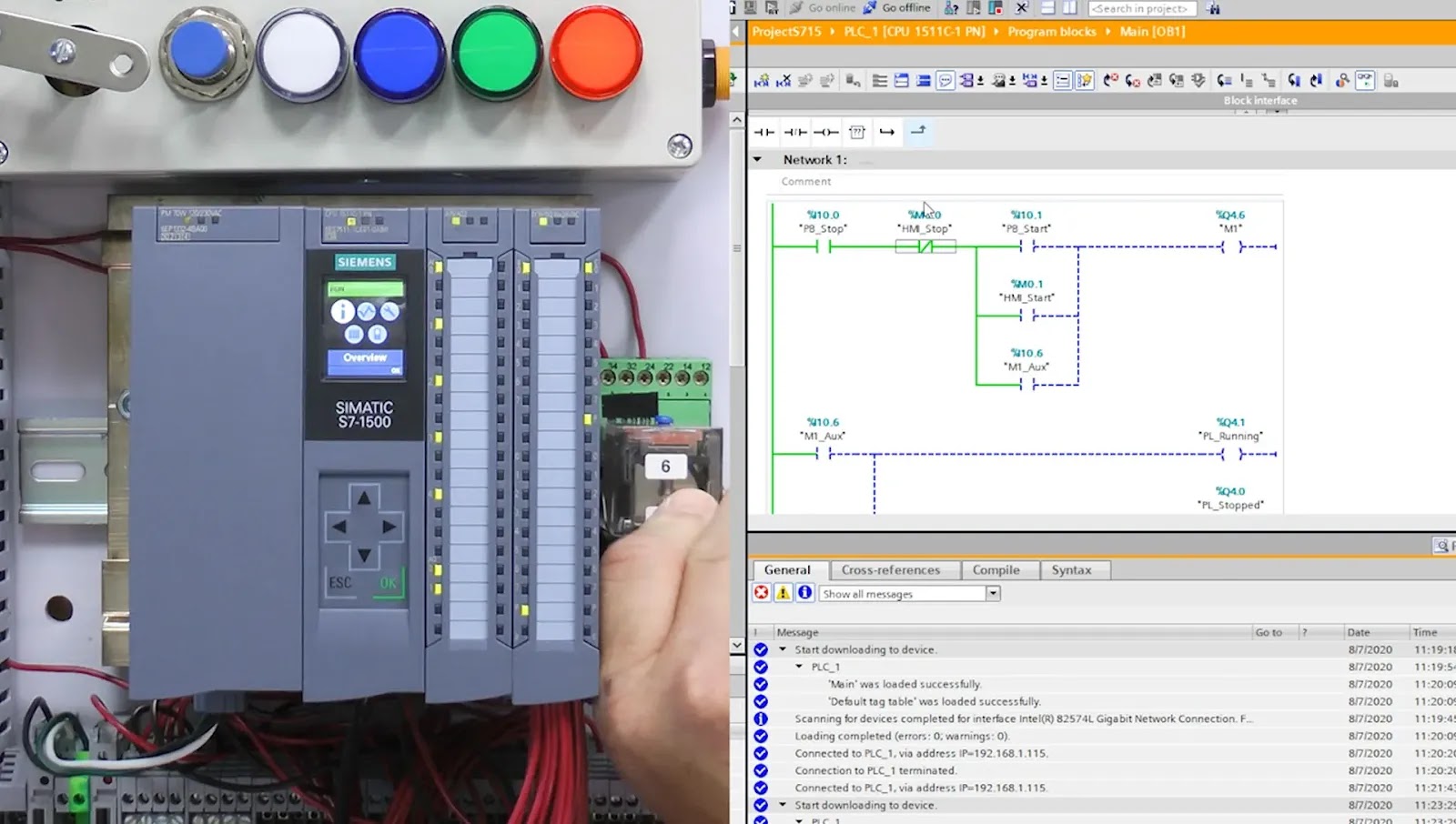

Programmable Logic Controllers (PLCs) are digital computers designed for industrial automation and control. They are crucial for managing and automating processes in various industries.

System Integration involves connecting various subsystems into a cohesive and efficient whole. It ensures that different components of your industrial operations work together smoothly.

With years of experience in PLC programming and system integration, our team at KSOFT ENGINEERING CONSULTANCY SERVICES offers unparalleled expertise. We provide customized solutions tailored to your specific needs, ensuring optimal performance and reliability.